Contact Us

Email: tzshunge@tzshunge.com

Email: sales1@tzshunge.com

Address: Dongcheng Street Daidong Village Huangyan District Taizhou City Zhejiang Province

0.6m3/300bar 1.0m3/300bar Air Tank for Blow Moulding Machine Bottle Making Machine

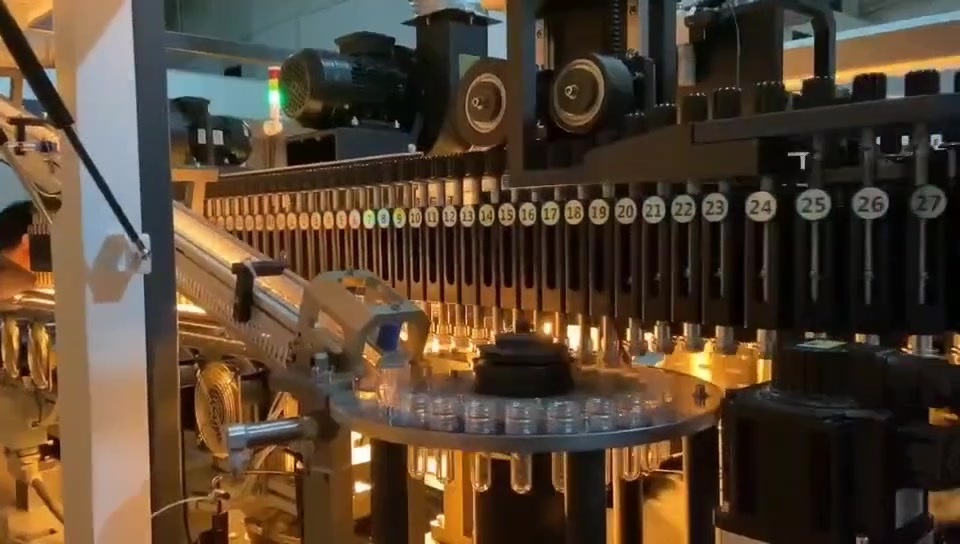

The air tank is an auxiliary machine for the bottle blowing machine. It stores compressed air, acting as a buffer to stabilize air pressure. This prevents pressure fluctuations caused by sudden air demand during the bottle blowing process, ensuring consistent and reliable operation of the machine.

Keywords: 182 Series Components | 210 Series Components

Category:

Product description

Previous

Hot 0.6m3/1.0m3 Air Tank for PET Plastic Mineral Water Stretch Blow Moulding Machine Bottle Making Machine

Application

Water Bottles

Beverage Bottles

Medicine Bottles

Space Cups

Products Video

video4

video3

video2

video1

Evaluation and transportation

Faq

How to extend the service life of the blowing machine?

How to maintain the mold of bottle blowing machine?

How to maintain the heating lamp of the blowing machine?

What are the possible reasons and solutions for the perforation of bottle bottom stretching?

How to avoid the problem of uneven wall thickness of PET bottle?

What are the possible reasons and solutions for the offset of the water spout position at the bottom of PET bottles?

Related Products

The air compressor is an auxiliary machine for the bottle blowing machine. It provides high-pressure compressed air, which is the power source for the bottle blowing process. This high-pressure air is used to inflate the preform, forcing it to expand and fit the shape of the mold cavity, thus forming the desired bottle shape.

The air compressor is an auxiliary machine for the bottle blowing machine. It provides high-pressure compressed air, which is the power source for the bottle blowing process. This high-pressure air is used to inflate the preform, forcing it to expand and fit the shape of the mold cavity, thus forming the desired bottle shape.

Low-Noise and High-Efficiency High-Pressure Air Compressor

The air compressor is an auxiliary machine for the bottle blowing machine. It provides high-pressure compressed air, which is the power source for the bottle blowing process. This high-pressure air is used to inflate the preform, forcing it to expand and fit the shape of the mold cavity, thus forming the desired bottle shape.

Meesage

If you are interested in our products and services, welcome to fill in your intentions and needs, and we will get in touch with you as soon as possible!