Contact Us

Email: sales1@tzshunge.com

Address: Dongcheng Street Daidong Village Huangyan District Taizhou City Zhejiang Province

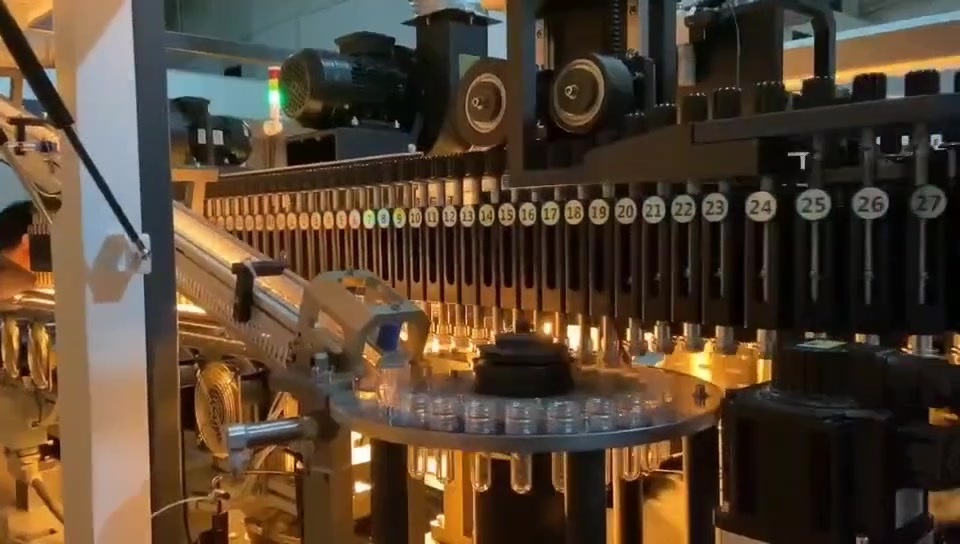

4 Cavity Factory Sale Automatic Small Plastic PET Drink Water Juice Bottle Jar Maker Stretch Blow Blowing Mold Making Machine

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle ,mineral water ,pesticide bottle,cosmetics bottle etc. Reasonable design,full automatic control,uniform heating,automatic feeding system save power and labor.

Keywords: 182 Series Components | 210 Series Components

Category:

Product description

| CONTAINER | SG-A4 |

| Theoretical output | 4500pcs/h |

| machine center distance | 120MM |

| Max container Vlolume | 2L |

| Max neck Diameter | 45MM |

| Max Container Diameter | 100MM |

| Max Container Height | 340MM |

| Number of Cavity | 4/Cavity |

| Number of light tube | / |

| He number of ovens 。 | / |

| Total Power | 30KW |

| Use Power | 20KW |

| Working pressure | 1.0Mpa |

| Low pressure Consuming | 1600Min |

| Blowing pressure | ≦3.0Mpa |

| High pressure Consuming | 2400Min |

| Machine Dimenson | 4500*1850*2100 |

| Machine Weight | 2500Kg |

| Feeding Machine Dimension | 1800*100*2000 |

| Feeding Machine Weight | 240kg |

Previous

Easy to Operate Full Automatic Plastic Mineral water cosmetics juice bottle Blow Molding Moulding Machine PET Blowing Machine

Application

Water Bottles

Beverage Bottles

Medicine Bottles

Space Cups

Products Video

video4

video3

video2

video1

Evaluation and transportation

FAQ

How to extend the service life of the blowing machine?

How to maintain the mold of bottle blowing machine?

How to maintain the heating lamp of the blowing machine?

What are the possible reasons and solutions for the perforation of bottle bottom stretching?

How to avoid the problem of uneven wall thickness of PET bottle?

What are the possible reasons and solutions for the offset of the water spout position at the bottom of PET bottles?

Related Products

The air compressor is an auxiliary machine for the bottle blowing machine. It provides high-pressure compressed air, which is the power source for the bottle blowing process. This high-pressure air is used to inflate the preform, forcing it to expand and fit the shape of the mold cavity, thus forming the desired bottle shape.

Factory 3HP 5HP Water-cooled Industrial Water Chiller for Bottle Making Blow Molding Machine

The water chiller is an auxiliary machine for the bottle blowing machine. Chillers can cool the molds to ensure product quality and efficient, continuous operation of the production line.

PET Oil Water Jar Bottle Mould for Automatic Bottle Making Blow Moulding Machine

It defines the shape and size of the final bottle. The cavity of the mold is precisely designed to match the desired dimensions, contours, and details (such as threads, logos, or grooves) of the bottle, ensuring each produced bottle conforms to the specified standards.

Meesage

If you are interested in our products and services, welcome to fill in your intentions and needs, and we will get in touch with you as soon as possible!